85 ถนนกาญจนาภิเษก แขวงบางบอนเหนือ เขตบางบอน กรุงเทพฯ 10150

Tel : +(66)2-899-6374 , +(66)86-308-0698

Fax : +(66)2-899-6371

E-mail : info@pcb-bangkok.com

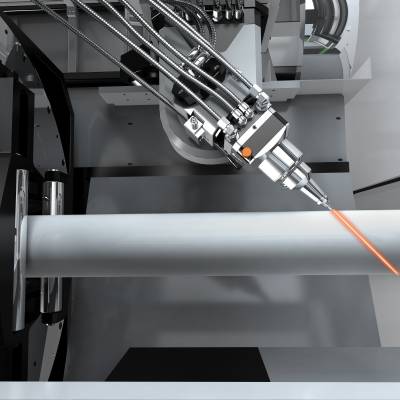

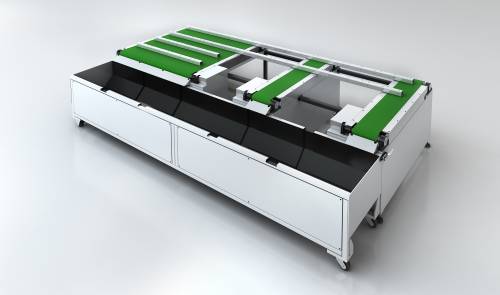

The swivel cutting head of the 3D 5-axis fiber laser pipe cutting machine can swing at positive and negative angles, and the cutting head forms a 45-degree bevel cut with the pipe surface, thereby realizing the pipe bevel cutting process. Compared with the traditional pipe cutting machine, the three-dimensional cutting ability is increased. Facilitate seamless welding.

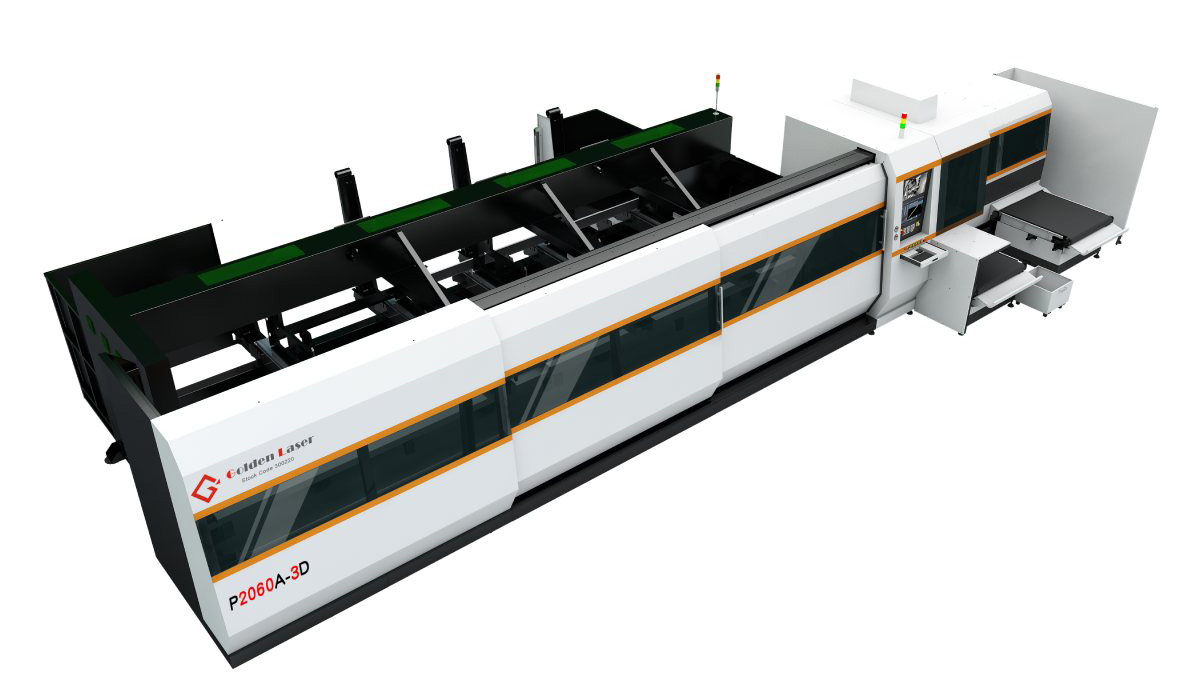

3D 5axis Fiber Laser Tube Cutting Machine - with Rotary 3D Laser Cutting Head for Tube Bevel Cutting... Suit for different shape groove bevel cutting on metal tubes, the tube outer diameter can be 20-200mm, metal tube length 6meter. With Auto tubes bundle loading system for automatic tube laser cutting process.

Model number : i 25 -3D / i 25A-3D / (P2560A-3D)

|

Rotary 3D Laser Cutting Head Imported from Germany

|

|

Groove Cutting Ability ( Beveling Ability) Excellent Groove Cutting Ability of the Pipe End Surface |

|

|

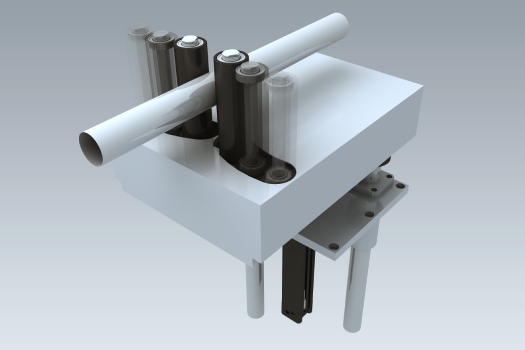

Floating Tubes Support System The Latest Floating Support System is Adopted.

|

|

Full-thickness Steel Plate Welding Machine Structure: The machine body is stable, has a long service life, and is not easily deformed. |

|

|

Auxiliary Feeding and Centering Device Two auxiliary feeding and centering devices are arranged at the front and back of the feeding end.

|

|

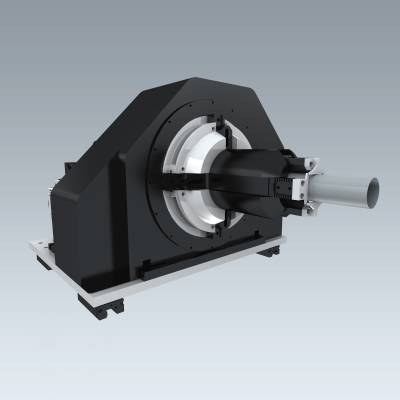

Professional Self-centering Pneumatic Chuck Clamping System The chuck is made of high-bearing steel material, with high sealing performance and good dynamic performance. |

|

|

Auxiliary Feeding and Centering Device

|

|

The Auto Bundle Loading System Improve Production Efficiency Tubes auto feeding system suit for 800*800mm bundle pipe loading. With automatic measure function to ensure loading the right pipe without any mistake. The alarm warning system reminds the operator during the whole production, PLC controller of the automatic loading system easy to adjust according to the detail processing demand, Autoloading, Your best choice for mass bevel cutting machine for pipes... |

|

3D Laser Tube Cutting Application:

Mainly for tube angle cutting, 45-degree angle cutting for Channel Steel, I-beam and so on.

3D laser tube cutting widely used in heavy machinery, Shipbuilding, construction industry and so on.

บทความและ Blog ที่เกี่ยวข้อง :

Fiber Laser cutting ไฟเบอร์เลเซอร์ 1-20 kw รับประกันนานสุด 5 ปี ราคาประหยัด ตัดหนาผิวเรียบสวย มุมคม แม่นยำ +/-0.03มม เริ่มต้นที่ 1.5 ลบ.